What is Polyurethane Foam Concrete Lifting

In short, polyurethane foam is the fastest, most cost-effective and Eco-friendly solution to lifting sunken, cracked concrete.

The polyurethane foam system combines the age-old technique of mudjacking with modern knowledge and technology. Instead of using a mixture of concrete and mud, this state-of-the-art approach utilizes high-density polyurethane foam that expands in the voids beneath the sinking, cracked concrete to lift back to a level position.

The Proven Solution

Concrete settlement is caused by changes in the moisture content and density of the soils beneath a concrete slab. Whether it be poorly compacted fill soils, a drought, or erosion, these changes create voids beneath the slab which eventually cause the concrete to crack, break and sink.

This is a very significant problem commonly seen in concrete Indianapolis foundation slabs, driveways, parking lots, patios, sidewalks and other walkways. The typical signs of concrete settlement are deep cracks, trip hazards, and pooling water.

The majority of property owners think that the only solution is the timely, and costly task of removing and then reconstructing the cracked or sunken concrete. In contrary, the cost-effective, polyurethane foam system offers the ability to repair and lift the damaged slab back to its original level in the shortest amount of time.

Advantages of Polyurethane Foam

- Fewer holes to drill saves a lot of time

- Smaller “Penny Sized” holes reduces patchwork

- Lightweight… only 4 lbs. per cubic yard opposed to the 120 lbs of mudjacking

- Immediate turnaround… walk or drive on 15 minutes after installation

- Environmentally friendly… made with 100% recycled materials

- Cost effective… minimal labor and complete in one day

- Non-Invasive… no need for reconstruction

- Non-Disruptive… no heavy, loud equipment involved

- Year-round installation in any weather condition

- Reduces trip hazards and restores property value

Can also be used for Additional Support

When used for lifting or leveling concrete Indianapolis foundation slabs, polyurethane foam may require additional support such as helical piers. This is because “foam lifting” doesn’t correct the underlying issue of soil conditions which caused the Indianapolis foundation or slab to move. The additional support helps achieve permanent structure stability to eliminate the possibility of future Indianapolis foundation damage.

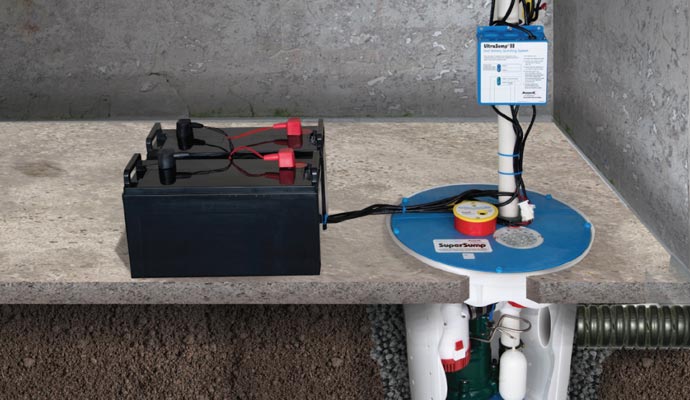

4 Step Installation Process

Installation involves drilling small (penny sized) holes into the damaged slab using specially designed equipment. Structural grade polymer is then injected into the voids beneath the concrete. Once the voids are filled, the expanding properties of the polyurethane allows for an accurate lift and leveling of the slab. Lastly, the small holes are grouted and sealed, leaving the slab completely restored.

- Step 1.

- Step 2.

- Step 3.

- Step 4.

Small 5/8-in. holes are bored through the sunken slab.

An injector port is installed in each hole.

High-density foam is injected into the port where upon it expands and lifts the slab.

With the port removed, the holes are cleaned and patched with cement.

Restore Your Property Value

In today’s market, any real estate professional will tell you the difficulties of selling a property with cracked, sunken concrete. And if left untreated, the price of a property may have to be discounted by up to 30% to sell. This amount is often far greater than the cost of the polyurethane repair. In short, you are saving money by addressing your concrete problems right away.

Details

Published: 26 June 2017